CNC Turned Components

Dowel Pins

Dowel pins are precision cylindrical fasteners used for accurate alignment and secure assembly in machinery, woodworking, and engineering applications.

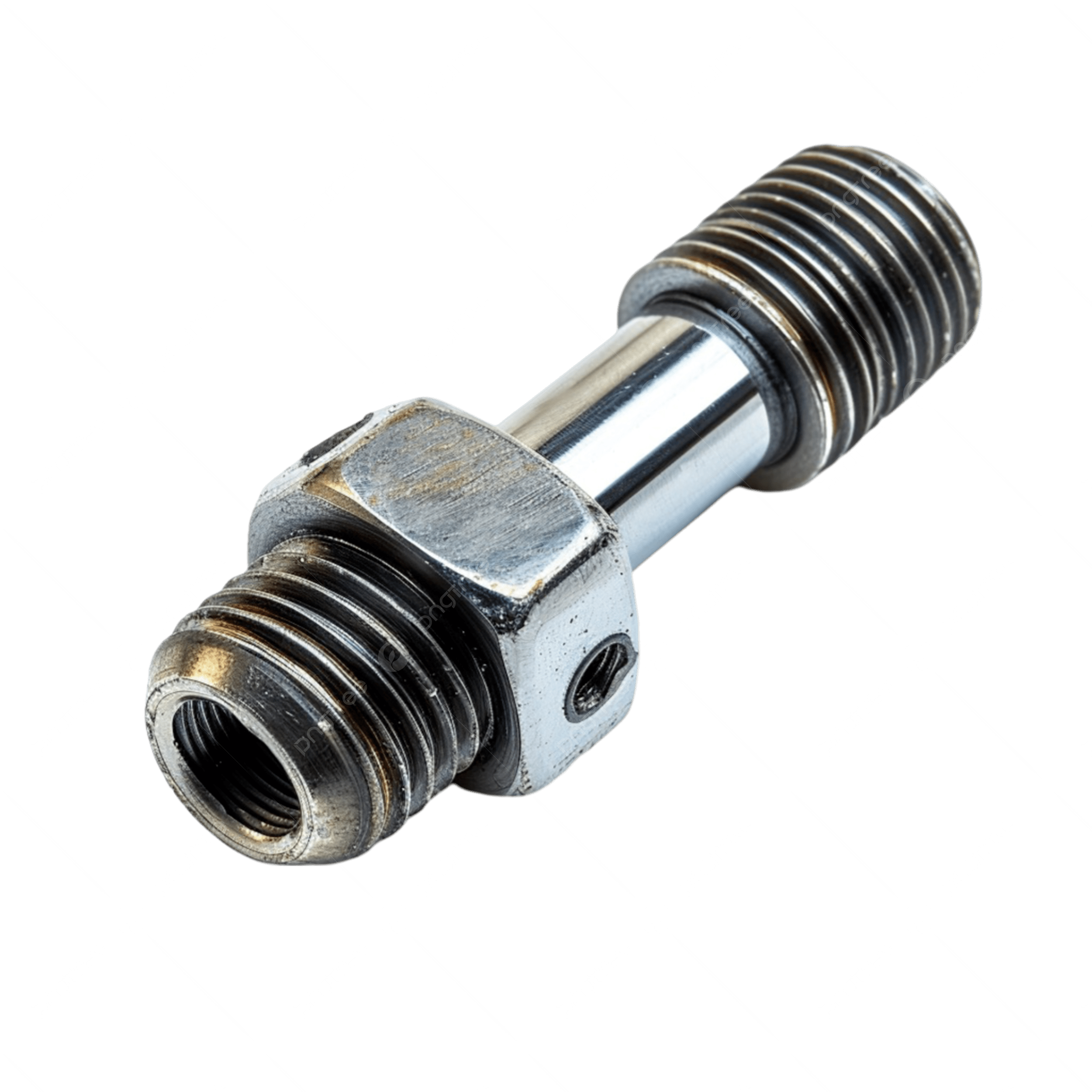

Special Turned Part

Threaded inserts are hardware components used to add durable, reusable threads to materials like plastic, wood, or soft metals, enhancing connection

Connectors

Connectors are electro-mechanical devices used to join electrical circuits, enabling reliable signal and power transmission across a wide range

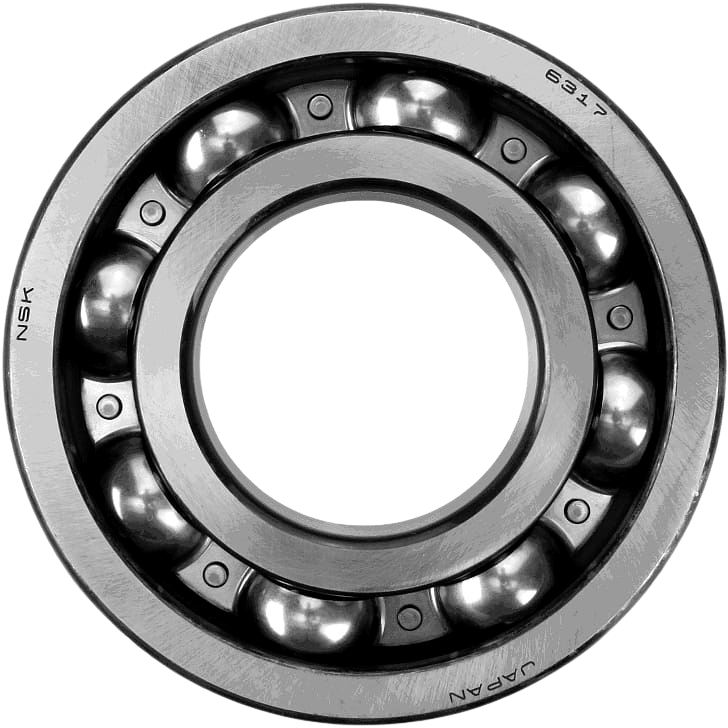

Bearing Part

Bearing parts are essential components—such as races, rollers, cages, and seals that enable smooth rotation, reduce friction, and support

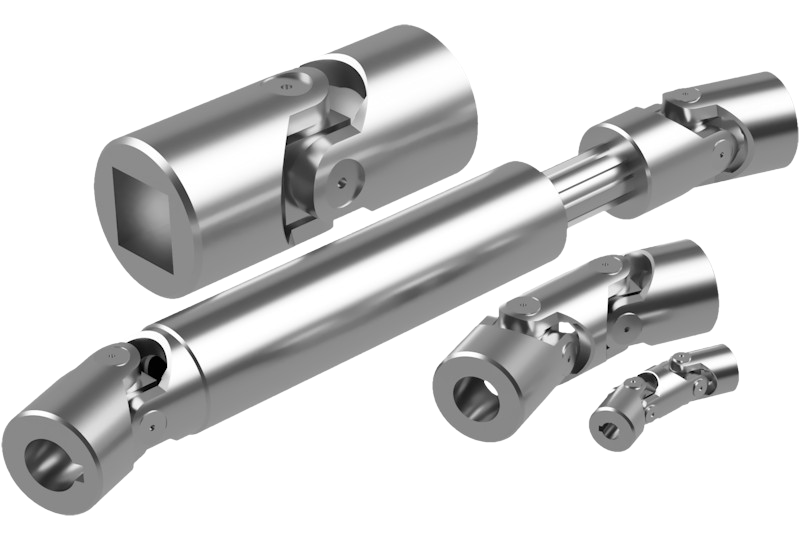

Universal Couplings

Universal couplings (or U-joints) are mechanical devices that transmit rotary motion between misaligned or angled shafts, commonly used in automotive

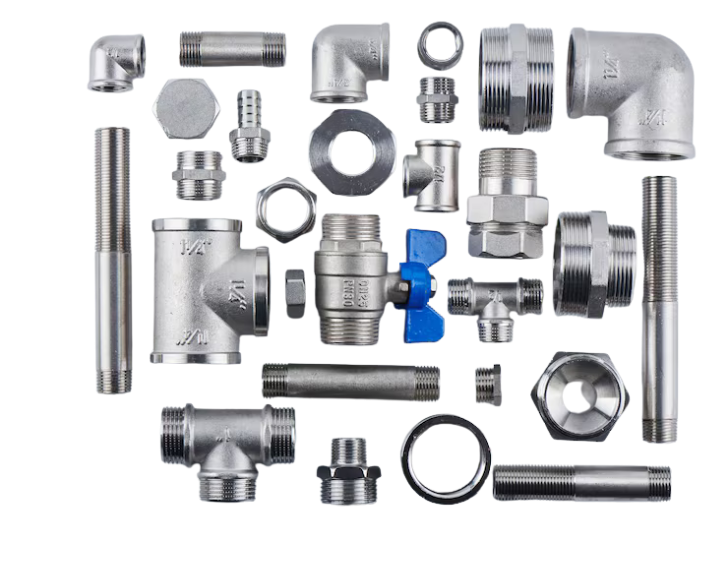

Pipe Fittings

Pipe fittings are components used to connect, divert, or regulate fluid flow in piping systems, including elbows, tees, couplings, and reducers